With a DTG printer, you can print lots of pattern T-shirts and provides them out to prospects and clients so they can literally put on your work and experience its high quality. A DTG printer allows you to render photographs in high-resolution, high-quality particulars, and you've got many colour choices.

The price for DTG ink is much higher than the cost for display printing ink. Since display printing sometimes is not profitable at small volumes, DTG printing offers a reasonable different for purchasers that need fewer than 12 pieces. The display screen is positioned on a display printing press and registered so it will correctly align on the printing floor (typically, a t-shirt). Ink is pressed through the openings within the stencil with a squeegee, immediately applying ink onto the printing floor. DTG is tremendous pricey, by far the costliest printing method.

Full color printing (like printing a shade photograph on a t-shirt) as a outcome of it has print cartridges which might print full color as easily as a single shade. In display printing, you must make a separate display screen for each colour of ink. You can advertise that your shop supplies no minimums, and full-color prints on mild or darkish garments. Plus, if a buyer asks for 3 to 5 or 10 more shirts, you possibly can fill reorders quickly and simply with little to no setup time. Typically, something as a lot as the 5-6 color vary will be good for display printing. Although we can print as much as 12+ colours per shirt, this won’t be economical until you’re printing giant quantities. Therefore, attempt to stay inside 5-6 colors as a good guideline.

One factor to contemplate is that we can all the time digitally print the entrance and display screen print the again or combine strategies to create one of the best product for your needs. Learning the entire technical terms of the garment printing trade are onerous and confusing! You can watch a short video to see how digital t-shirt printing is done. Read on to assist decipher the difference between digital printing vs display screen printing strategies and become an industry expert! Heck, even sometimes business professionals are confused concerning the differences between digital apparel printing and screen printing shirts. It's not as easy as one being "higher" than the other, it's a query of which one better suits your needs! Check out our information beneath to determine if Screen Printing or Digital Printing is more beneficial in in your custom attire project!

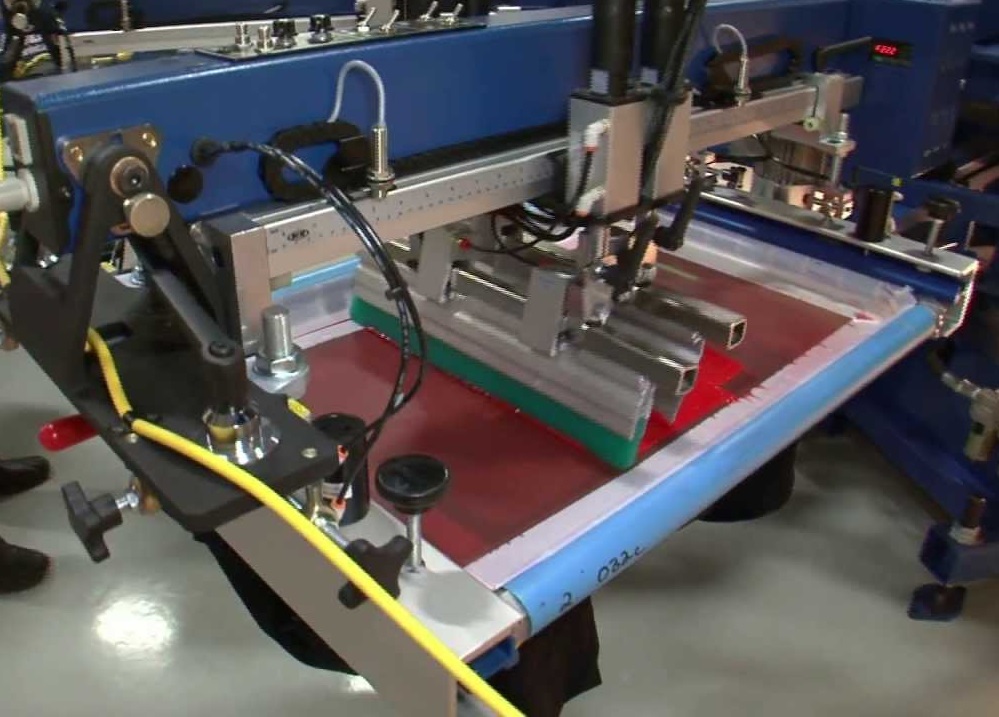

Screen printing pushes ink by way of a display screen onto a shirt. Because each diy screen printing display screen can only have one colour, it’s better for prints with lower amount of colors. Also, it is constructed for velocity and can print several hundred shirts per hour. Distressed-look display screen printing also can create a softer hand by lowering the amount of surface area the ink occupies and breaking it up so it’s extra versatile.

A display screen printer will use single permeable screens, on which ink is positioned to be pulled throughout the material in a sample dictated by the stencil placed on the mesh itself. We also supply warmth transfers at a 20 piece minimal order amount and people are dearer than screen printing across the similar value for direct to garment. This technique is nice for materials which have a water-resistant coating or with a lot of seams that might sometimes hinder printing.

For instance, a guide store goes to have a lower minimal than an automated shop. A larger shop with an in-house artist who can do separations is going to have extra expertise doing multicolor jobs using simulated and true course of vs. a smaller shop. Our marketing campaign builder the best approach to start promoting T-shirts online. This printing model offers you the freedom to introduce new designs or enter new markets without dropping any cash. If the product doesn’t sell, you'll be able to discontinue or substitute it. Direct-to-garment printing is a hassle-free approach to get the products prepared on your clients. Because it requires upfront funding and quite a bit of your time to get the designs print-ready.

The vinyl can be applied to all kinds of fabric – cotton, polyester, nylon, and so on. It’s quite time consuming – it takes plenty of time to cut out the vinyl and weed it out. That’s why you can’t use this methodology to work on massive orders. Cut the vinyl – the cutter has blades that cut the form you design out of the vinyl. Create a design – some machines come with software but you possibly can just use an exterior graphics design software program to give you a design. For instance, using puff with high-density and suede, you can create a pretend tackle-twill, mesh or even embroidered look, complete with faux stitching.

Keep in thoughts, if you’ve been tasked with printing some shirts for the office, your greatest wager is to discover a good display screen printer in your area. If you don’t have paintings available, you possibly can attempt companies like Fiverr.com or Upwork.com, where you'll be able to work with designers for as low as $5 to $10 per design.

The printing is of very prime quality – the printer produces full colour images. Then once more, the printers needed plenty of upkeep and weren't very user-friendly. The current fashions have climbed to a complete new level – they can print on darker-colored clothes utilizing lighter-colored inks without any points and they're a lot more user-friendly. [newline]The tools utilized in display screen printing are quite bulky and need plenty of house – most definitely not a back-office affair. Here are the benefits and drawbacks of utilizing warmth transfer to print apparels. Matching colours accurately is especially necessary in terms of corporate branding.Many firms have model tips that specify Pantone colours. If you attempt to match those colors with DTG, they’re nearly at all times going to be off. The main cause is that the underbase isn’t opaque sufficient, so the shirt color bleeds by way of.

Depending on the specifics of your customized printing project, one will likely be a higher option than the opposite. The largest differences that you want to contemplate when choosing a technique fall into two basic categories — design andcost. This is a more recent t-shirt printing method that’s gained plenty of popularity lately because of technological improvements in DTG printers. DTG printing creates a precisely printed design with a high stage of element. Both the printing strategies are appropriate for t-shirts, hoodies, sweatshirts, and so forth. Screen printing is typically done by making use of ink by way of a mesh-like stencil of the design. This is mostly a guide process, and therefore labor-intensive.

Or, you presumably can stack high-density until you get a print so raised it seems like an appliqué. You don’t want to give somebody road rash from hugging them. A quality DTG print can potentially get dozens of washes before it begins fading. As a college student, I was all the time thinking about saving cash any means that I may. I’ve discovered a lot through the years from folks keen to offer again, and wish to cross that data on to others.

Instead of using screens to apply the ink to the garment, DTG printing truly uses something like an inkjet printer to print the ink instantly onto the material. This methodology is prepared to take very intricate, detailed designs and an excellent multitude of colors and apply them with relative ease. The largest distinction is that DTG will most probably be a cheaper price for tasks that require multiple colors to be printed. Instead of having to order a big qty of every colour combination you presumably can order smaller minimums. DTG also doesn’t require a screen to be made, so there are not any setup fees. Screen printing is cost-effective for larger runs of simpler designs with fewer colours.

The Ovaljet machines are primarily based on the DTG printing technique that uses a closed-loop technology where every garment moves through a sequence of automated stations. This supplies for smooth DTG printing and production efficiency. Water-based ink takes time to absorb and then treatment or set to maneuver on to other processes like applying different print screens. This slowdown of display printing is inefficient when pitted towards DTG printing. Screen printing is most cost-effective for larger batches of shirts. The stencil course of means that set-up prices are a little higher, nevertheless it also makes screen printing extra efficient for big orders of 1 design.

Although the machine needs guide labor to function it, it is bulletproof! Any breakdowns that do happen are uncommon and are tough to troubleshoot. Most of those machines are well-setup with out anticipating problems. When you first begin printing your t-shirts, the primary choice to make is the printing technique.

100% cotton might be the commonest materials, and is what pretty much all low cost shirts are made of. That being said, some one hundred pc cotton shirts can get expensive. Gildan might be the most typical industry-standard brand, and is an effective finances alternative in case you are planning on printing more than about 50 shirts. They are all the time in inventory, and actually wash up pretty well. I’ve never had an issue with the standard Gildan Ultra Cotton t-shirts earlier than, and display screen printers at all times have the Gildan model in stock.